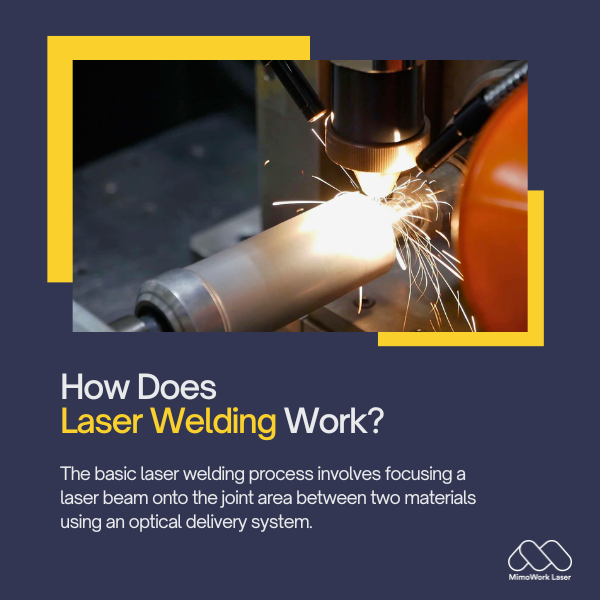

Cov txheej txheem vuam laser yooj yim yog siv lub tshuab xa khoom siv optical los tsom lub teeb laser rau ntawm qhov sib koom ua ke ntawm ob yam khoom. Thaum lub teeb kov cov khoom, nws hloov nws lub zog, ua kom sov sai thiab yaj ib cheeb tsam me me.

Cov Ntsiab Lus

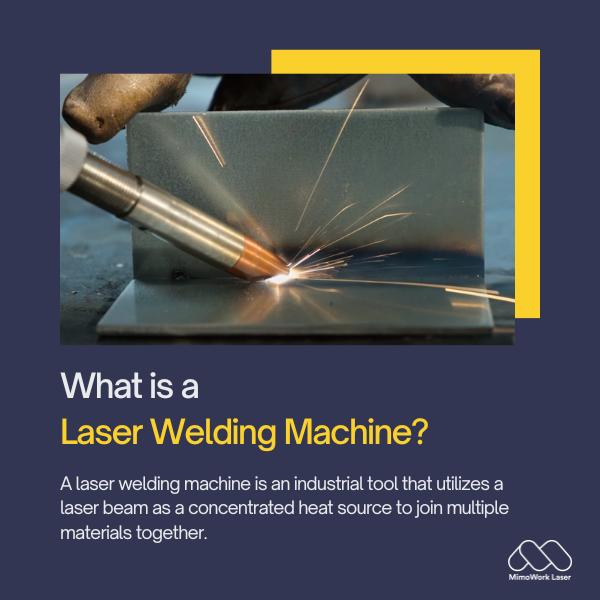

1. Lub Tshuab Laser Welding yog dab tsi?

Lub tshuab laser vuam yog ib lub cuab yeej kev lag luam uas siv lub teeb laser ua lub hauv paus cua sov kom sib koom ua ke ntau yam khoom siv.

Qee qhov tseem ceeb ntawm cov tshuab laser welding muaj xws li:

1. Qhov Chaw Laser:Feem ntau cov tshuab laser welders niaj hnub no siv cov solid-state laser diodes uas tsim cov teeb laser muaj zog heev hauv cov spectrum infrared. Cov khoom siv laser feem ntau suav nrog CO2, fiber, thiab diode lasers.

2. Kev Pom Kev:Cov teeb laser taug kev hla ntau yam khoom siv kho qhov muag xws li daim iav, lub lens, thiab lub nozzles uas tsom thiab coj cov teeb mus rau thaj chaw vuam nrog kev raug. Cov caj npab telescoping lossis gantries tso cov teeb.

3. Kev siv tshuab ua haujlwm:Muaj ntau lub tshuab vuam laser uas siv computer numerical control (CNC) thiab robotics los ua kom cov qauv vuam thiab cov txheej txheem vuam nyuaj. Cov kev programmable thiab cov sensors feedback ua kom muaj qhov tseeb.

4. Kev Saib Xyuas Txheej Txheem:Cov koob yees duab sib xyaw ua ke, cov spectrometers, thiab lwm yam sensors saib xyuas cov txheej txheem vuam tam sim ntawd. Txhua yam teeb meem nrog kev sib dhos ntawm lub beam, kev nkag mus, lossis qhov zoo tuaj yeem nrhiav tau thiab daws tau sai.

5. Kev Sib Txuas Lus Kev Nyab Xeeb:Cov tsev tiv thaiv, qhov rooj, thiab cov nyees khawm e-stop tiv thaiv cov neeg teb xov tooj ntawm lub teeb laser muaj zog heev. Cov interlocks kaw lub laser yog tias cov txheej txheem kev nyab xeeb raug ua txhaum.

Yog li ntawd, hauv kev xaus, lub tshuab vuam laser yog lub khoos phis tawj tswj hwm, cov cuab yeej siv kev lag luam uas siv lub teeb laser tsom rau kev siv tshuab, rov ua dua daim ntawv thov vuam.

2. Laser Vuam Ua Haujlwm Li Cas?

Qee cov theem tseem ceeb hauv cov txheej txheem laser welding suav nrog:

1. Kev Tsim Lub Teeb Laser:Ib lub laser diode solid-state lossis lwm qhov chaw tsim tawm lub teeb infrared.

2. Kev Xa Khoom Beam: Cov iav, cov iav tsom iav, thiab lub nozzle tsom lub teeb kom meej rau qhov chaw nruj ntawm qhov workpiece.

3. Cov Khoom Siv Cua Sov:Lub teeb ua kom cov khoom kub sai sai, nrog rau qhov ceev ze li ntawm 106 W / cm2.

4. Yaj thiab koom ua ke:Ib lub pas dej me me uas yaj ua rau cov khoom sib xyaw ua ke. Thaum lub pas dej khov, qhov sib txuas yuav tsim.

5. Txias thiab Rov khov dua: Thaj chaw vuam txias ntawm qhov kub siab tshaj 104 ° C / ob, tsim kom muaj cov qauv me me, tawv.

6. Kev nce qib:Lub nqaj txav mus los yog cov khoom raug hloov chaw thiab cov txheej txheem rov ua dua kom tiav qhov vuam seam. Cov roj inert shielding kuj tseem siv tau.

Yog li ntawd, hauv kev xaus, laser welding siv lub teeb laser uas tsom mus rau qhov muaj zog thiab kev tswj hwm thermal cycling los tsim cov welds zoo, tsis muaj cua sov cuam tshuam.

Peb Muab Cov Lus Qhia Pab Tau Txog Cov Tshuab Vuam Laser

Ib yam li Cov Kev Daws Teeb Meem Tshwj Xeeb Rau Koj Lub Lag Luam

3. Puas yog Laser Welding zoo dua li MIG?

Thaum piv rau cov txheej txheem vuam hlau inert gas (MIG) ib txwm muaj ...

Laser welding muaj ntau yam zoo:

1. Kev Ntsuas Tseeb: Cov teeb laser tuaj yeem tsom mus rau qhov chaw me me 0.1-1 hli, ua rau muaj kev vuam zoo heev, rov ua dua. Qhov no zoo tagnrho rau cov khoom me me, ua haujlwm tau ntev.

2. Ceev:Cov nqi vuam rau lub laser yog sai dua li MIG, tshwj xeeb tshaj yog rau cov ntsuas nyias dua. Qhov no ua rau kev tsim khoom zoo dua thiab txo lub sijhawm voj voog.

3. Zoo:Qhov chaw kub uas muaj zog ua rau muaj kev cuam tshuam tsawg kawg nkaus thiab nqaim thaj chaw cuam tshuam los ntawm cua sov. Qhov no ua rau muaj kev vuam zoo thiab muaj zog.

4. Kev siv tshuab ua haujlwm:Kev vuam laser yooj yim siv tshuab los ntawm kev siv robotics thiab CNC. Qhov no ua rau cov qauv nyuaj thiab zoo sib xws dua li kev vuam MIG tes.

5. Cov ntaub ntawv:Lasers tuaj yeem koom ua ke ntau yam khoom siv, suav nrog ntau yam khoom siv thiab cov hlau sib txawv.

Txawm li cas los xij, MIG welding muajqee qhov zoodhau laser hauv lwm daim ntawv thov:

1. Tus nqi:Cov khoom siv MIG muaj tus nqi pib qis dua li cov tshuab laser.

2. Cov ntaub ntawv tuab dua:MIG zoo dua rau kev vuam cov hlau tuab dua 3 hli, qhov twg kev nqus laser tuaj yeem muaj teeb meem.

3. Cov roj tiv thaiv:MIG siv cov roj inert los tiv thaiv thaj chaw vuam, thaum laser feem ntau siv txoj kab teeb ci.

Yog li ntawd, hauv kev xaus, laser welding feem ntau yog qhov nyiam raukev ua haujlwm raug, kev tswj hwm tsis siv neeg, thiab kev vuam zoo.

Tab sis MIG tseem sib tw rau kev tsim khoomcov ntsuas tuab dua ntawm cov peev nyiaj tsawg.

Cov txheej txheem zoo nyob ntawm daim ntawv thov vuam tshwj xeeb thiab cov kev xav tau ntawm ib feem.

4. Puas Yog Laser Vuam Zoo Dua Li TIG Vuam?

Tungsten inert gas (TIG) vuam yog ib qho txheej txheem tes ua, kev txawj ntse uas tuaj yeem tsim cov txiaj ntsig zoo heev ntawm cov ntaub ntawv nyias.

Txawm li cas los xij, laser vuam muaj qee qhov zoo dua li TIG:

1. Ceev:Kev vuam laser sai dua li TIG rau cov ntawv thov ntau lawm vim nws qhov kev ua haujlwm raug. Qhov no ua rau muaj kev ua haujlwm ntau dua.

2. Kev Ntsuas Tseeb:Lub teeb laser uas tsom mus rau qhov chaw tso cai rau qhov tseeb ntawm qhov chaw mus txog rau hauv ib puas feem pua ntawm ib millimeter. Qhov no tsis tuaj yeem sib phim los ntawm tes tib neeg nrog TIG.

3. Kev Tswj:Cov txheej txheem hloov pauv xws li cua sov nkag thiab weld geometry raug tswj hwm nruj nrog lub laser, kom ntseeg tau tias cov txiaj ntsig zoo sib xws.

4. Cov ntaub ntawv:TIG zoo tshaj plaws rau cov ntaub ntawv nyias nyias, thaum laser vuam qhib ntau yam kev sib xyaw ua ke ntawm ntau yam khoom.

5. Kev siv tshuab ua haujlwm: Cov tshuab laser robotic ua rau kev vuam tsis siv neeg kiag li yam tsis muaj kev qaug zog, thaum TIG feem ntau xav tau kev saib xyuas thiab kev txawj ntse ntawm tus neeg teb xov tooj.

Txawm li cas los xij, TIG welding tseem muaj qhov zoo raukev ua haujlwm precision nyias-gauge lossis kev vuam hlauqhov twg cov cua sov nkag yuav tsum tau ua tib zoo modulate. Rau cov ntawv thov no, tus kws tshaj lij kov yog qhov tseem ceeb.

5. Qhov Tsis Zoo ntawm Laser Welding yog dab tsi?

Ib yam li lwm yam txheej txheem kev lag luam, laser welding muaj qee qhov tsis zoo uas yuav tsum xav txog:

1. Tus nqi: Txawm hais tias pheej yig dua, cov tshuab laser muaj zog siab xav tau kev nqis peev ntau piv rau lwm txoj kev vuam.

2. Cov Khoom Siv Tau:Cov roj nozzles thiab optics lwj zuj zus raws sijhawm thiab yuav tsum tau hloov, ntxiv rau tus nqi ntawm kev muaj.

3. Kev Nyab Xeeb:Yuav tsum muaj cov txheej txheem nruj thiab cov tsev kaw neeg kom tiv thaiv kev raug rau lub teeb laser muaj zog heev.

4. Kev Kawm:Cov neeg teb xov tooj xav tau kev cob qhia kom ua haujlwm tau zoo thiab tswj cov khoom siv laser vuam kom zoo.

5. Kab pom kev:Lub teeb laser taug kev ua kab ncaj, yog li cov duab geometries nyuaj yuav xav tau ntau lub teeb lossis hloov chaw ua haujlwm.

6. Kev Nqus Tau:Tej yam khoom siv xws li hlau tuab lossis txhuas yuav nyuaj rau vuam yog tias lawv tsis nqus tau lub laser qhov wavelength tshwj xeeb kom zoo.

Txawm li cas los xij, nrog kev ceev faj, kev cob qhia, thiab kev ua kom zoo dua qub, laser welding muab kev tsim khoom, kev ua kom raug, thiab qhov zoo rau ntau daim ntawv thov kev lag luam.

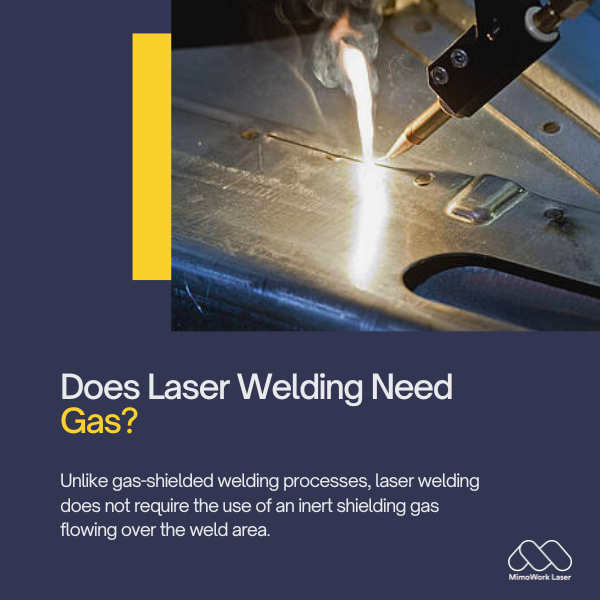

6. Puas Yog Laser Welding Xav Tau Roj?

Tsis zoo li cov txheej txheem vuam uas muaj roj tiv thaiv, kev vuam laser tsis tas yuav siv cov roj tiv thaiv inert uas ntws hla thaj chaw vuam. Qhov no yog vim:

1. Lub teeb laser uas tsom mus rau saum huab cua mus tsim ib lub pas dej me me, muaj zog heev uas yaj thiab koom nrog cov ntaub ntawv.

2. Huab cua nyob ib puag ncig tsis ionized zoo li cov roj plasma arc thiab tsis cuam tshuam rau lub beam lossis weld tsim.

3. Cov hlau vuam khov sai heev los ntawm qhov kub uas nws tsim ua ntej cov oxides tuaj yeem tsim rau ntawm qhov chaw.

Txawm li cas los xij, qee qhov kev siv laser vuam tshwj xeeb tseem yuav tau txais txiaj ntsig los ntawm kev siv roj pab:

1. Rau cov hlau uas muaj zog xws li txhuas, roj tiv thaiv lub pas dej vuam kub ntawm cov pa oxygen hauv huab cua.

2. Thaum siv laser ua haujlwm siab, roj ua rau cov plasma plume uas tsim thaum lub sijhawm vuam tob.

3. Cov roj dav hlau tshem tawm cov pa phem thiab cov khib nyiab kom xa tau cov teeb pom kev zoo dua ntawm cov chaw qias neeg lossis pleev xim.

Yog li ntawd, hauv kev xaus, txawm hais tias tsis tsim nyog kiag li, cov roj inert yuav muab cov txiaj ntsig rau cov ntawv thov laser vuam lossis cov ntaub ntawv nyuaj. Tab sis cov txheej txheem feem ntau tuaj yeem ua tau zoo yam tsis muaj nws.

Yuav luag txhua yam hlau tuaj yeem raug laser welded suav nroghlau, txhuas, titanium, nickel alloys, thiab lwm yam.

Txawm tias cov hlau sib txawv sib xyaw ua ke los kuj ua tau. Qhov tseem ceeb yog lawvyuav tsum nqus tau qhov wavelength laser kom zoo.

Cov ntawv nyias li0.1 hli thiab tuab li 25 hlifeem ntau tuaj yeem ua laser welded, nyob ntawm daim ntawv thov tshwj xeeb thiab lub zog laser.

Cov ntu tuab dua yuav xav tau kev vuam ntau zaus lossis cov khoom siv tshwj xeeb.

Kiag li. Cov hlwb hlau laser vuam feem ntau siv rau hauv kev kub ceev, tsis siv neeg ntau lawm rau cov ntawv thov xws li kev tsim khoom tsheb.

Cov nqi throughput ntawm ntau meters ib feeb yog ua tau.

Cov ntawv thov laser welding feem ntau tuaj yeem pom hauvtsheb, khoom siv hluav taws xob, khoom siv kho mob, aerospace, cuab yeej/tuag, thiab kev tsim khoom me me precision.

Cov thev naus laus zis yogtxuas ntxiv mus rau hauv cov lag luam tshiab.

Cov yam uas yuav tsum xav txog suav nrog cov ntaub ntawv ua haujlwm, qhov loj / tuab, qhov xav tau ntawm kev ua haujlwm, peev nyiaj, thiab qhov zoo ntawm kev vuam.

Cov neeg muag khoom muaj npe nrov tuaj yeem pab qhia meej txog hom laser, lub zog, optics, thiab automation rau koj daim ntawv thov tshwj xeeb.

Cov txheej txheem vuam laser ib txwm muaj xws li butt, lap, fillet, piercing, thiab cladding welds.

Qee txoj kev tshiab xws li kev tsim khoom siv laser additive kuj tseem tab tom tshwm sim rau kev kho thiab kev siv prototyping.

Yog, laser welding yog qhov zoo rau kev kho kom raug ntawm cov khoom muaj nqis siab.

Qhov cua sov uas muaj zog ua rau txo qhov kev puas tsuaj ntxiv rau cov ntaub ntawv hauv paus thaum kho.

Xav pib nrog lub tshuab laser welder?

Vim li cas ho tsis xav txog peb?

Lub sijhawm tshaj tawm: Lub Ob Hlis-12-2024