Usoro ịgbado ọkụ laser bụ isi gụnyere itinye ogwe laser n'elu ebe njikọ dị n'etiti ihe abụọ site na iji sistemụ nnyefe anya. Mgbe ogwe ahụ metụrụ ihe ndị ahụ aka, ọ na-ebufe ike ya, na-ekpo ọkụ ma na-agbaze obere mpaghara ngwa ngwa.

Isiokwu Ọdịnaya

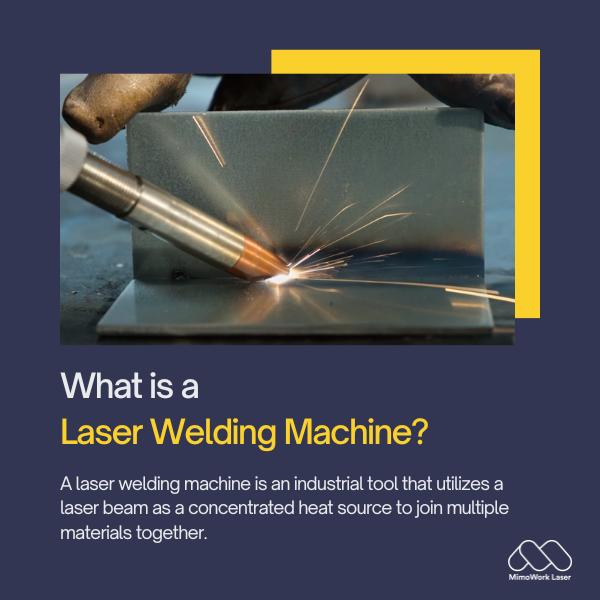

1. Gịnị bụ igwe ịgbado ọkụ laser?

Igwe ịgbado ọkụ laser bụ ngwa ọrụ mmepụta ihe nke na-eji ogwe laser dị ka isi iyi okpomọkụ siri ike ijikọta ọtụtụ ihe ọnụ.

Ụfọdụ isi ihe dị mkpa nke igwe ịgbado ọkụ laser gụnyere:

1. Isi Iyi Laser:Ọtụtụ ndị na-agbado ọkụ laser nke oge a na-eji diode laser siri ike nke na-emepụta ìhè laser dị ike na infrared spectrum. Isi mmalite laser ndị a na-ahụkarị gụnyere CO2, eriri, na diode lasers.

2. Ngwa anya:Ìhè laser ahụ na-agafe n'usoro ihe ndị dị ka enyo, lensị, na nozzles nke na-elekwasị anya ma na-eduzi ogwe ahụ gaa na mpaghara njikọta ahụ nke ọma. Ogwe aka ma ọ bụ ihe ndị na-egosi oghere ahụ na-etinye ogwe ahụ.

3. Akpaaka:Ọtụtụ ndị na-agbado ọkụ laser nwere njikọta njikwa ọnụọgụgụ kọmputa (CNC) na robotik iji mee ka usoro na usoro ịgbado ọkụ dị mgbagwoju anya rụọ ọrụ. Ụzọ mmemme na ihe mmetụta nzaghachi na-eme ka o doo anya na ha ziri ezi.

4. Nlekota Usoro:Igwefoto, ihe nlele anya, na ihe mmetụta ndị ọzọ ejikọtara ọnụ na-enyocha usoro ịgbado ọkụ n'oge. Enwere ike ịchọpụta ma dozie nsogbu ọ bụla metụtara nhazi nke ìhè, ntinye aka, ma ọ bụ ịdị mma.

5. Nchekwa Njikọ:Ebe nchekwa, ọnụ ụzọ, na bọtịnụ e-stop na-echebe ndị ọrụ site na ọkụ laser dị elu. Mkpọchi ndị dị n'etiti na-emechi laser ahụ ma ọ bụrụ na emebie usoro nchekwa.

Ya mere, na nchịkọta, igwe ịgbado ọkụ laser bụ ngwaọrụ nhazi nke kọmputa na-achịkwa, nke na-eji oghere laser lekwasịrị anya maka ngwa ịgbado ọkụ akpaka, nke a na-emegharị ugboro ugboro.

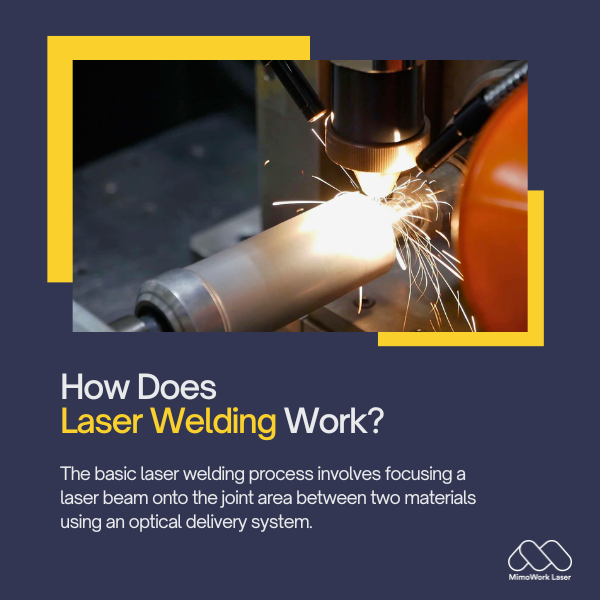

2. Kedu ka ịgbado ọkụ laser si arụ ọrụ?

Ụfọdụ isi usoro na laser welding gụnyere:

1. Mmepụta ọkụ laser:Diode laser siri ike ma ọ bụ isi iyi ọzọ na-emepụta oghere infrared.

2. Nnyefe ọkụ: Enyo, lensị, na ihe mkpuchi na-etinye ìhè ahụ kpọmkwem n'ebe siri ike n'elu ihe e ji arụ ọrụ ahụ.

3. Ịkpo ọkụ ihe:Osisi ahụ na-ekpo ọkụ ngwa ngwa, njupụta ya na-eru nso 106 W/cm2.

4. Ịgbaze na Ịjikọta:Obere ọdọ mmiri na-agbaze agbaze na-etolite ebe ihe ndị e ji mee ya na-agbakọta. Ka ọdọ mmiri ahụ na-esi ike, a na-emepụta njikọ njikọta.

5. Ịjụ oyi na ime ka ọ sie ike ọzọ: Ebe a na-agbakọta ihe na-ajụ oyi n'ọkwa dị elu karịa 104°C/sekọnd, na-emepụta obere ihe owuwu siri ike ma sie ike.

6. Ọganihu:Ogwe osisi ahụ na-agagharị ma ọ bụ na-agbanwe akụkụ ya, usoro ahụ na-emegharị iji mezue njikọta njikọta ahụ. Enwere ike iji gas na-echebe ihe na-adịghị ike.

Ya mere, na nchịkọta, ịgbado ọkụ laser na-eji ọkụ laser a na-elekwasị anya nke ọma na ịgbado ọkụ okpomọkụ a na-achịkwa iji mepụta njikọta mpaghara dị elu, nke okpomọkụ na-emetụta nke ọma.

Anyị nyere ozi bara uru gbasara igwe ịgbado ọkụ laser

Yana Ngwọta ahaziri maka azụmaahịa gị

3. Ịgbado ọkụ laser ọ ka mma karịa MIG?

Ma e jiri ya tụnyere usoro ịgbado ọkụ nke igwe anaghị agba nchara (MIG) ọdịnala...

Ịmepụta laser nwere ọtụtụ uru:

1. Nkenke: Enwere ike itinye oghere laser n'ebe dị obere nke dị 0.1-1mm, nke na-eme ka njikọta ahụ dị mfe ma dịkwa mfe ịgbagharị. Nke a dị mma maka obere akụkụ ndị nwere ike ịnagide ya nke ọma.

2. Ọsọ:Ọnụego ịgbado ọkụ maka laser dị ngwa karịa MIG, ọkachasị na ihe nlele dị gịrịgịrị. Nke a na-eme ka mmepụta ihe ka mma ma na-ebelata oge okirikiri.

3. Ogo:Isi iyi okpomọkụ a na-eme ka ọ ghara ịdị mma ma ọ bụ nwee obere nsogbu na mpaghara ndị okpomọkụ na-emetụta. Nke a na-eme ka ọ nwee ike ịgbado ọkụ dị elu ma sie ike.

4. Akpaaka:A na-eji robotik na CNC agbado ọkụ laser ngwa ngwa. Nke a na-eme ka usoro dị mgbagwoju anya na nhazi ka mma karịa ịgbado ọkụ MIG aka.

5. Ihe eji eme ihe:Lasers nwere ike ijikọ ọtụtụ ngwakọta ihe, gụnyere njikọta ígwè dị iche iche na nke dị iche iche.

Agbanyeghị, njikọta MIG nwere ikike dị elu.ụfọdụ urun'ime ngwa ndị ọzọ, ọ bụghị laser:

1. Ọnụ ego:Ngwaọrụ MIG nwere ọnụ ahịa itinye ego mbụ dị ala karịa sistemụ laser.

2. Ihe ndị dị oke arọ:MIG ka mma maka ịgbado akụkụ ígwè dị oke ibu karịa 3mm, ebe nnabata laser nwere ike ịkpata nsogbu.

3. Gas nchekwa:MIG na-eji ihe mkpuchi gas na-adịghị arụ ọrụ iji chebe ebe a na-agbakọta ihe, ebe laser na-ejikarị ụzọ osisi eme ihe.

Ya mere, na nchịkọta, a na-ahọrọkarị ịgbado ọkụ laser makankenke, akpaaka, na ịdị mma ịgbado ọkụ.

Mana MIG ka na-asọmpi maka mmepụtanha ndị buru ibu na mmefu ego.

Usoro ziri ezi dabere na ngwa ịgbado ọkụ kpọmkwem na ihe achọrọ maka akụkụ.

4. Ịkụnye ọkụ n'ime laser ọ̀ ka mma karịa ịgbado ọkụ n'ime TIG?

Ịkwado Tungsten inert gas (TIG) bụ usoro aka, nke nwere nkà nka nke nwere ike ịrụpụta ezigbo ihe na ihe ndị dị gịrịgịrị.

Agbanyeghị, ịgbado ọkụ laser nwere ụfọdụ uru karịa TIG:

1. Ọsọ:Ịgbado ọkụ laser dị ngwa karịa TIG maka ngwa mmepụta n'ihi na ọ na-arụ ọrụ na akpaghị aka. Nke a na-eme ka mmepụta ya ka mma.

2. Nkenke:Ogbugba laser a lekwasịrị anya na-enye ohere ka nhazi ya ruo n'ime otu narị milimita. Aka mmadụ nwere TIG enweghị ike ijikọ nke a.

3. Njikwa:A na-ejikwa laser achịkwa mgbanwe usoro dị ka ntinye okpomọkụ na geometry ịgbado ọkụ nke ọma, na-eme ka o kwe omume na otu ahụ ga-enweta nsonaazụ na-adịgide adịgide n'otu oge.

4. Ihe eji eme ihe:TIG kacha mma maka ihe ndị na-eduzi ihe dị gịrịgịrị, ebe njikọta laser na-emepe ọtụtụ ngwakọta dị iche iche.

5. Akpaaka: Sistemụ laser robot na-eme ka ịgbado ọkụ na-akpaghị aka kpamkpam na-enweghị ike ọgwụgwụ, ebe TIG na-achọkarị nlebara anya na ahụmịhe zuru oke nke onye ọrụ.

Agbanyeghị, njikọta TIG na-enye uru dị ukwuu makaọrụ nhazi dị gịrịgịrị ma ọ bụ ịgbado ọkụ alloyebe a ga-eji nlezianya gbanwee ntinye okpomọkụ. Maka ngwa ndị a, mmetụ aka ọkachamara nwere nkà bara uru.

5. Gịnị bụ ọghọm dị na ịgbado ọkụ laser?

Dịka ọ dị na usoro mmepụta ihe ọ bụla, njikọta laser nwere ụfọdụ ihe ndọghachi azụ:

1. Ọnụ ego: Ọ bụ ezie na ọ na-adị ọnụ ala karịa, sistemụ laser dị elu chọrọ nnukwu itinye ego na isi obodo ma e jiri ya tụnyere ụzọ ịgbado ọkụ ndị ọzọ.

2. Ihe oriri:Ngwunye gas na ihe anya na-emebi ka oge na-aga, a ga-agbanwekwa ha, nke na-eme ka ọnụ ahịa nke onye nwe ha dịkwuo elu.

3. Nchekwa:A chọrọ usoro siri ike na ebe nchekwa dị n'ime ya iji gbochie ikpughe na ọkụ laser dị ike.

4. Ọzụzụ:Ndị ọrụ chọrọ ọzụzụ iji rụọ ọrụ n'enweghị nsogbu na idozi akụrụngwa ịgbado ọkụ laser nke ọma.

5. Ahịrị anya:Ogbugba laser ahụ na-aga n'ahịrị kwụ ọtọ, yabụ geometry dị mgbagwoju anya nwere ike ịchọ ọtụtụ ogidi ma ọ bụ nhazigharị ọrụ.

6. Ịmịkọrọ ihe:Ụfọdụ ihe dịka ígwè dị arọ ma ọ bụ aluminom nwere ike isi ike ịgbado ọkụ ma ọ bụrụ na ha anaghị anabata ogologo ebili mmiri nke laser nke ọma.

Agbanyeghị, site na iji nlezianya, ọzụzụ, na nhazi usoro kwesịrị ekwesị, ịgbado ọkụ laser na-enye mmepụta, nkenke, na uru dị mma maka ọtụtụ ngwa ụlọ ọrụ mmepụta ihe.

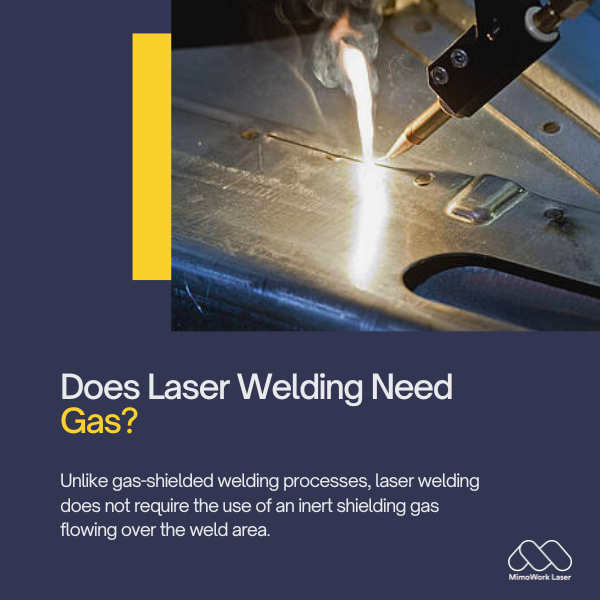

6. Ịkwado ọkụ laser ọ dị mkpa ka gas dị?

N'adịghị ka usoro ịgbado ọkụ nke gas na-echebe, ịgbado ọkụ laser anaghị achọ iji gas na-echebe ihe na-adịghị agbanwe agbanwe na-agafe ebe ịgbado ọkụ ahụ. Nke a bụ n'ihi:

1. Ìhè laser a lekwasịrị anya na-agafe n'ikuku iji mepụta obere ọdọ mmiri ịgbado ọkụ dị elu nke na-agbaze ma jikọta ihe ndị ahụ.

2. Ikuku gbara ya gburugburu anaghị agwakọta ion dị ka gas plasma arc, ọ naghịkwa egbochi nhazi nke ramụ ma ọ bụ weld.

3. Njikọta ahụ na-esi ike ngwa ngwa site na okpomọkụ siri ike nke na ọ na-etolite tupu oxides enwee ike ịpụta n'elu.

Agbanyeghị, ụfọdụ ngwa ịgbado ọkụ laser pụrụ iche ka nwere ike irite uru site na iji gas enyemaka:

1. Maka ọla ndị na-emegharị ahụ dịka aluminom, gas na-echebe ọdọ mmiri ọkụ site na ikuku oxygen.

2. N'ọrụ laser nwere ike dị elu, gas na-eme ka ihe mkpuchi plasma nke na-etolite n'oge njikọta miri emi.

3. Ụgbọelu gas na-ekpochapụ anwụrụ ọkụ na ihe mkpofu ka e wee nwee ike ibufe ọkụ n'elu ihe ruru unyi ma ọ bụ nke e sere ese nke ọma.

Ya mere, na nchịkọta, ọ bụ ezie na ọ bụghị ihe dị mkpa kpọmkwem, gas na-adịghị arụ ọrụ nwere ike inye uru maka ngwa ma ọ bụ ihe ndị siri ike maka ịgbado ọkụ laser. Mana usoro a nwere ike ịrụ ọrụ nke ọma na-enweghị ya.

Ihe fọrọ nke nta ka ọ bụrụ ígwè niile ka enwere ike ịgbado ọkụ laser gụnyereígwè, aluminom, titanium, nickel alloy, na ihe ndị ọzọ.

Ọ ga-ekwe omume ọbụna njikọta ígwè dị iche iche. Isi ihe dị na ya bụ na haaghaghị ịmịkọrọ ogologo oge laser nke ọma.

Mpempe akwụkwọ dị gịrịgịrị dịka0.1mm na oke ọkpụrụkpụ: 25mmenwere ike iji laser welded mee ya, dabere na ngwa a kapịrị ọnụ yana ike laser.

Ngalaba ndị buru ibu nwere ike ịchọ ịgbado ọkụ dị iche iche ma ọ bụ ihe pụrụ iche.

N'ezie. A na-ejikarị ígwè ọrụ ịgbado ọkụ laser robot eme ihe n'ebe mmepụta ngwa ngwa, nke akpaaka maka ngwa dịka imepụta ụgbọala.

A na-enweta ike ọsọ nke ọtụtụ mita kwa nkeji.

Enwere ike ịchọta ngwa ịgbado ọkụ laser nkịtị naụgbọala, ngwa eletrọnịkị, ngwaọrụ ahụike, ụgbọelu, ngwaọrụ/anwụ, na imepụta akụkụ dị obere kpọmkwem.

Teknụzụ bụna-agbasa n'ime ngalaba ọhụrụ mgbe niile.

Ihe ndị a ga-atụle gụnyere ihe e ji arụ ọrụ, nha/ọkpụrụkpụ ya, mkpa mmepụta ya, mmefu ego ya, na ịdị mma nke ịgbado ọkụ ya.

Ndị na-ebubata ihe a ma ama nwere ike inye aka chọpụta ụdị laser, ike, optics, na akpaghị aka kwesịrị ekwesị maka ngwa gị kpọmkwem.

Usoro ịgbado ọkụ laser a na-ejikarị eme ihe gụnyere ike, ụkwụ, eriri, ịkpọpu ihe, na ịgbado ihe mkpuchi.

Ụfọdụ ụzọ ọhụrụ dịka imepụta ihe mgbakwunye laser na-apụtakwa maka ngwa ndozi na imepụta ihe atụ.

Ee, ịgbado ọkụ laser dị mma maka nrụzi ziri ezi nke ihe ndị dị oke ọnụ ahịa.

Ntinye okpomọkụ a na-etinye na-ebelata mmebi ọzọ na ihe ndị bụ isi n'oge ndozi.

Ị chọrọ ịmalite igwe laser welder?

Gịnị mere na ị gaghị echebara anyị echiche?

Oge ozi: Febụwarị-12-2024