Inqubo eyisisekelo yokushisela nge-laser ihilela ukugxila umsebe we-laser endaweni ehlangene phakathi kwezinto ezimbili kusetshenziswa uhlelo lokulethwa kwe-optical. Lapho umsebe uthinta izinto, udlulisela amandla awo, ufudumale ngokushesha futhi uncibilikise indawo encane.

Uhlu Lokuqukethwe

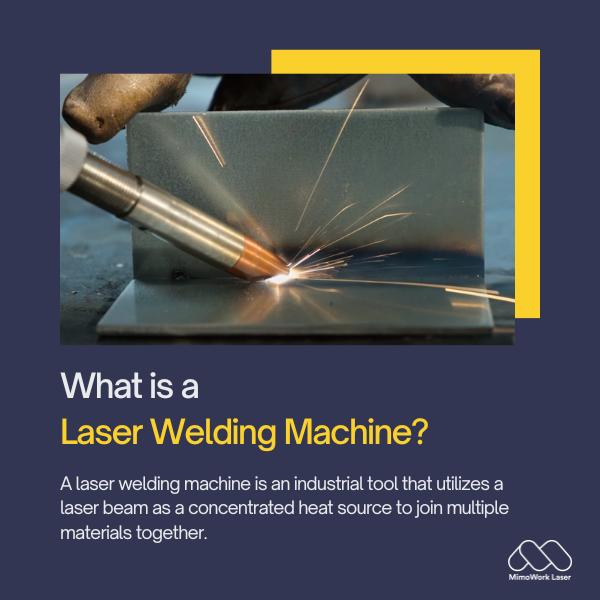

1. Uyini Umshini Wokushisela Nge-Laser?

Umshini wokushisela nge-laser uyithuluzi lezimboni elisebenzisa umsebe we-laser njengomthombo wokushisa ohlanganisiwe ukuhlanganisa izinto eziningi ndawonye.

Ezinye izici ezibalulekile zemishini yokushisela nge-laser zifaka:

1. Umthombo We-Laser:Iningi labashiseli be-laser banamuhla basebenzisa ama-diode e-laser aqinile akhiqiza umsebe we-laser onamandla aphezulu ku-spectrum ye-infrared. Imithombo evamile ye-laser ihlanganisa ama-laser e-CO2, i-fiber, kanye ne-diode.

2. Ama-Optics:Ugongolo lwe-laser luhamba ochungechungeni lwezingxenye ezibonakalayo njengezibuko, amalensi, nama-nozzle agxila futhi aqondise ugongolo endaweni yokushisela ngokunemba. Izingalo noma ama-gantries asebenzisa i-telescoping abeka ugongolo.

3. Ukuzenzakalela:Ama-laser welder amaningi afaka ukuhlanganiswa kokulawulwa kwezinombolo zekhompyutha (i-CNC) kanye namarobhothi ukuze enze ngokuzenzakalelayo amaphethini nezinqubo zokushisela eziyinkimbinkimbi. Izindlela ezihlelwayo kanye nezinzwa zempendulo ziqinisekisa ukunemba.

4. Ukuqapha Inqubo:Amakhamera ahlanganisiwe, ama-spectrometer, nezinye izinzwa ziqapha inqubo yokushisela ngesikhathi sangempela. Noma yiziphi izinkinga ngokulungiswa kwemisebe, ukungena, noma ikhwalithi zingatholakala futhi zixazululwe ngokushesha.

5. Izingidi Zokuphepha:Izivalo ezivikelayo, iminyango, kanye nezinkinobho ze-e-stop zivikela opharetha emsebeni we-laser onamandla amakhulu. Izingidi ezixhumeneyo ziyayivala i-laser uma kuphulwa imigomo yokuphepha.

Ngakho-ke ngamafuphi, umshini wokushisela nge-laser uyithuluzi elilawulwa yikhompyutha, elinokunemba kwezimboni elisebenzisa umsebe we-laser ogxile ekusetshenzisweni kokushisela okuzenzakalelayo nokuphindaphindekayo.

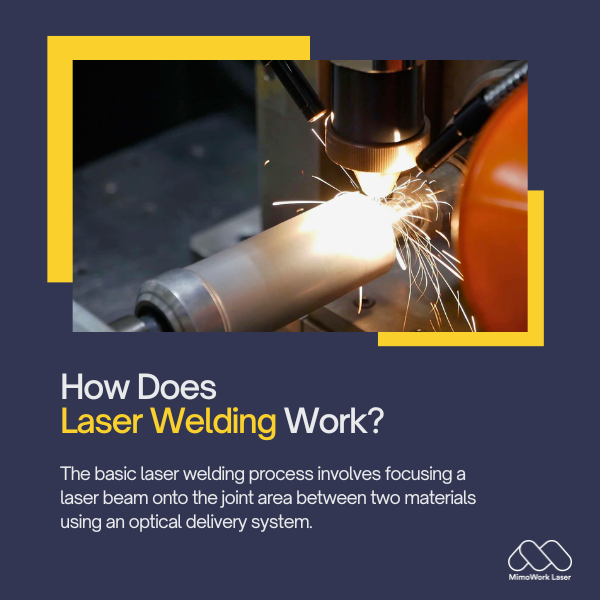

2. Kusebenza Kanjani Ukushisela Nge-Laser?

Ezinye izigaba ezibalulekile enqubweni yokushisela nge-laser zifaka:

1. Ukukhiqizwa Kwemisebe Yelaser:I-diode ye-laser yesimo esiqinile noma omunye umthombo ukhiqiza umsebe we-infrared.

2. Ukulethwa Kwemisebe: Izibuko, amalensi, kanye nomlomo ocijile kugxilisa kahle ugongolo endaweni eqinile ku-workpiece.

3. Ukushisa Izinto:Ugongolo lushisa ngokushesha izinto, ngobuningi obusondela ku-106 W/cm2.

4. Ukuncibilikisa Nokuhlanganisa:Idamu elincane elincibilikayo lakha lapho izinto zihlangana khona. Njengoba ichibi liqina, kwakheka i-weld joint.

5. Ukupholisa Nokuqinisa Kabusha: Indawo yokushisela iphola ngamazinga aphezulu angaphezu kuka-104°C/umzuzwana, okudala isakhiwo esincane esiqinile nesinohlamvu oluncane.

6. Intuthuko:Ukunyakaza kwensimbi noma izingxenye ziphinde zibekwe endaweni yazo bese inqubo iphinda ukuze kuqedwe umthungo wokushisela. Igesi yokuvikela engangenisi lutho ingasetshenziswa futhi.

Ngakho-ke ngamafuphi, ukushisela nge-laser kusebenzisa umsebe we-laser ogxile kakhulu kanye nokujikeleza kokushisa okulawulwayo ukukhiqiza ukushisela kwe-zone okuseqophelweni eliphezulu, okuphansi okuthinteke ekushiseni.

Sinikeze Ulwazi Oluwusizo Ngemishini Yokushisela Nge-Laser

Kanye Nezixazululo Ezenziwe Ngokwezifiso Zebhizinisi Lakho

3. Ingabe ukushisela nge-laser kungcono kune-MIG?

Uma kuqhathaniswa nezinqubo zokushisela zendabuko zegesi yensimbi engenasici (i-MIG)...

Ukushisela nge-laser kunezinzuzo eziningana:

1. Ukunemba: Imisebe ye-laser ingagxiliswa endaweni encane engu-0.1-1mm, okwenza kube lula ukushintshwa okunembile kakhulu nokuphindekayo. Lokhu kulungele izingxenye ezincane, ezibekezelela kakhulu.

2. Isivinini:Amazinga okushisela e-laser ashesha kakhulu kune-MIG, ikakhulukazi kuma-gauge amancane. Lokhu kuthuthukisa umkhiqizo futhi kunciphisa izikhathi zomjikelezo.

3. Ikhwalithi:Umthombo wokushisa ogxilile ukhiqiza ukuphambuka okuncane kanye nezindawo ezincane ezithintekile ekushiseni. Lokhu kuphumela ekushiseni okuqinile nokusezingeni eliphezulu.

4. Ukuzenzakalela:Ukushisela nge-laser kwenziwa ngokuzenzakalelayo kusetshenziswa amarobhothi kanye ne-CNC. Lokhu kwenza amaphethini ayinkimbinkimbi kanye nokuqiniswa okuthuthukisiwe uma kuqhathaniswa nokushisela nge-MIG ngesandla.

5. Izinto zokwakha:Ama-laser angahlanganisa izinhlanganisela eziningi zezinto, okuhlanganisa ukushintshwa kwensimbi okunezinto eziningi kanye nokungafanani.

Kodwa-ke, ukushisela kwe-MIG kunayoizinzuzo ezithilengaphezu kwe-laser kwezinye izinhlelo zokusebenza:

1. Izindleko:Imishini ye-MIG inezindleko zokutshalwa kwezimali kokuqala eziphansi kunezinhlelo ze-laser.

2. Izinto ezijiyile:I-MIG ifaneleka kangcono ekushiseleni izingxenye zensimbi ezijiyile ezingaphezu kuka-3mm, lapho ukumuncwa kwe-laser kungaba yinkinga.

3. Igesi yokuvikela:I-MIG isebenzisa isivikelo segesi esingasebenzi ukuvikela indawo yokushisela, kuyilapho i-laser ivame ukusebenzisa indlela yokubopha evaliwe.

Ngakho-ke ngamafuphi, ukushisela nge-laser ngokuvamile kukhethwa kakhuluukunemba, ukuzenzekela, kanye nekhwalithi yokushisela.

Kodwa i-MIG isalokhu incintisana ekukhiqizweni kwe-amageyiji amakhulu ngesabelomali esincane.

Inqubo efanele incike ekusetshenzisweni okuthile kokushisela kanye nezidingo zezingxenye.

4. Ingabe Ukushisela Nge-Laser Kungcono Kunokushisela Nge-TIG?

Ukushisela igesi ye-tungsten inert (TIG) kuyinqubo eqhutshwa ngesandla, enekhono lobuciko engaveza imiphumela emihle kakhulu ezintweni ezincane.

Noma kunjalo, ukushisela nge-laser kunezinzuzo ezithile ngaphezu kwe-TIG:

1. Isivinini:Ukushisela nge-laser kushesha kakhulu kune-TIG ekusetshenzisweni kokukhiqiza ngenxa yokunemba kwayo okuzenzakalelayo. Lokhu kuthuthukisa ukusebenza kahle.

2. Ukunemba:Ukukhanya kwe-laser okugxilile kuvumela ukunemba kokubeka endaweni okungaphakathi kwengxenye eyodwa kweziyikhulu zamamilimitha. Lokhu akunakulinganiswa nesandla somuntu nge-TIG.

3. Ukulawula:Izinguquko zenqubo ezifana nokufakwa kokushisa kanye ne-weld geometry zilawulwa ngokuqinile nge-laser, okuqinisekisa imiphumela ehambisanayo nge-batch phezu kwe-batch.

4. Izinto zokwakha:I-TIG ingcono kakhulu ezintweni ezithwala umoya ezincane, kuyilapho ukushisela nge-laser kuvula izinhlobonhlobo eziningi zezinhlanganisela zezinto eziningi.

5. Ukuzenzakalela: Izinhlelo ze-laser zamarobhothi zivumela ukushisela okuzenzakalelayo ngokuphelele ngaphandle kokukhathala, kuyilapho i-TIG ngokuvamile idinga ukunakwa okugcwele kanye nobuchwepheshe bomqhubi.

Kodwa-ke, ukushisela kwe-TIG kugcina inzuzoumsebenzi wokunemba we-thin-gauge noma ukushisela i-alloylapho ukufakwa kokushisa kumele kushintshwe ngokucophelela. Kulezi zinhlelo zokusebenza ukuthinta kochwepheshe onekhono kubalulekile.

5. Iyini Inkinga Yokushisela Nge-Laser?

Njenganoma iyiphi inqubo yezimboni, ukushisela nge-laser kunezinkinga ezithile ezingaba khona okufanele uzicabangele:

1. Izindleko: Nakuba ziba zingabizi kakhulu, izinhlelo ze-laser ezinamandla aphezulu zidinga ukutshalwa kwezimali okukhulu uma kuqhathaniswa nezinye izindlela zokushisela.

2. Izinto ezisetshenziswayo:Ama-nozzle egesi kanye nama-optics ayawohloka ngokuhamba kwesikhathi futhi kumele ashintshwe, okwengeza ezindlekweni zobunikazi.

3. Ukuphepha:Kudingeka izinqubo eziqinile kanye nezindawo zokuphepha ezivalekile ukuze kuvinjelwe ukuchayeka emsebeni we-laser onamandla aphezulu.

4. Ukuqeqeshwa:Abasebenzi badinga ukuqeqeshwa ukuze basebenze ngokuphepha futhi banakekele kahle imishini yokushisela nge-laser.

5. Umugqa wokubona:Ugongolo lwe-laser luhamba ngemigqa eqondile, ngakho-ke amajiyomethri ayinkimbinkimbi angadinga imishayo eminingi noma ukuhlelwa kabusha kwezingxenye zomsebenzi.

6. Ukumunca:Izinto ezithile ezifana nensimbi ejiyile noma i-aluminium kungaba nzima ukuzishisela uma zingamunci kahle ubude be-wavelength be-laser.

Nokho, ngezinyathelo zokuqapha ezifanele, ukuqeqeshwa, kanye nokwenza ngcono izinqubo, ukushisela nge-laser kuletha ukukhiqiza, ukunemba, kanye nezinzuzo zekhwalithi ezinhlelweni eziningi zezimboni.

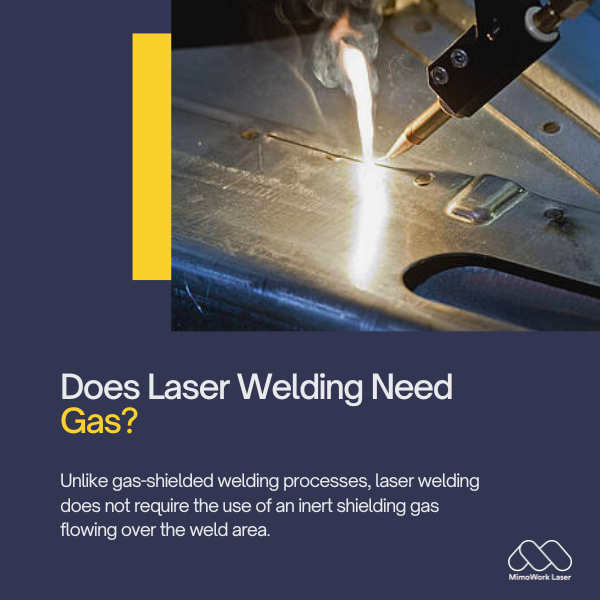

6. Ingabe Ukushisela Nge-Laser Kudinga Igesi?

Ngokungafani nezinqubo zokushisela ezivikelwe ngegesi, ukushisela nge-laser akudingi ukusetshenziswa kwegesi yokuvikela engasebenzi kahle egeleza endaweni yokushisela. Lokhu kungenxa yokuthi:

1. Ugongolo lwe-laser olugxilile luhamba emoyeni ukuze ludale ichibi elincane, elinamandla amakhulu lokushisela elincibilikisa futhi lihlanganise izinto.

2. Umoya ozungezile awufakwanga i-ion njenge-gas plasma arc futhi awuphazamisi ukwakheka kwe-beam noma i-weld.

3. I-weld iqina ngokushesha okukhulu kusukela ekushiseni okugxilile kangangokuthi yakheka ngaphambi kokuba ama-oxide akheke phezu komhlaba.

Kodwa-ke, ezinye izinhlelo zokusebenza ezikhethekile zokushisela nge-laser zingase zizuze ngokusebenzisa igesi yokusiza:

1. Ngezinsimbi ezisabelayo njenge-aluminium, igesi ivikela ichibi lokushiswa elishisayo emoyeni.

2. Emisebenzini ye-laser enamandla amakhulu, igesi iqinisa i-plasma plume eyakheka ngesikhathi sokushintshwa kokungena okujulile.

3. Amajethi egesi asusa umusi kanye nemfucumfucu ukuze kube lula ukudlulisa imisebe ezindaweni ezingcolile noma ezipendiwe.

Ngakho-ke ngamafuphi, nakuba kungadingeki kakhulu, igesi engasebenzi inganikeza izinzuzo zezinhlelo zokusebenza noma izinto zokushisela nge-laser eziyinselele. Kodwa inqubo ivame ukusebenza kahle ngaphandle kwayo.

Cishe zonke izinsimbi zingashintshwa nge-laser okuhlanganisainsimbi, i-aluminium, i-titanium, ama-alloy e-nickel, nokuningi.

Ngisho nokuhlanganiswa kwensimbi okungafani kungenzeka. Isihluthulelo ukuthikumele imunce ubude be-laser kahle.

Amashidi amancane njenge0.1mm futhi ubukhulu obungafika ku-25mmngokuvamile ingashintshwa nge-laser, kuye ngokuthi isicelo esithile kanye namandla e-laser asebenza kanjani.

Izingxenye ezijiyile zingadinga ukushisela okudlula okuningi noma i-optics ekhethekile.

Impela. Amaseli okushisela nge-laser yerobhothi avame ukusetshenziswa ezindaweni zokukhiqiza ezisheshayo nezizenzakalelayo zezinhlelo zokusebenza ezifana nokukhiqiza izimoto.

Amazinga okudlula kwamamitha amaningana ngomzuzu angafinyeleleka.

Izinhlelo zokusebenza zokushisela nge-laser ezivamile zingatholakala kuizimoto, izinto zikagesi, amadivayisi ezokwelapha, izindiza, amathuluzi/i-die, kanye nokukhiqizwa kwezingxenye ezincane ngokunemba.

Ubuchwepheshe buyiikhula njalo ibe yimikhakha emisha.

Izinto okufanele uzicabangele zifaka phakathi izinto zokusebenza, usayizi/ukujiya, izidingo zokukhiqiza, isabelomali, kanye nekhwalithi yokushisela edingekayo.

Abahlinzeki abadumile bangasiza ekucaciseni uhlobo lwe-laser olufanele, amandla, ukukhanya, kanye nokwenza izinto ngokuzenzakalela kohlelo lwakho lokusebenza oluthile.

Amasu ajwayelekile okushisela nge-laser ahlanganisa ukushisela kwe-butt, i-lap, i-fillet, ukubhoboza, kanye ne-cladding.

Ezinye izindlela ezintsha ezifana nokukhiqizwa kwezengezo ze-laser nazo ziyavela ukuze kulungiswe futhi kusetshenziswe izinhlelo zokusebenza ze-prototyping.

Yebo, ukushisela nge-laser kufaneleka kahle ekulungisweni okunembile kwezingxenye zenani eliphezulu.

Ukufakwa kokushisa okugxilile kunciphisa umonakalo owengeziwe ezintweni eziyisisekelo ngesikhathi sokulungiswa.

Ufuna Ukuqala Ngomshini Wokushisela We-Laser?

Kungani Ungacabangi Ngathi?

Isikhathi sokuthunyelwe: Feb-12-2024