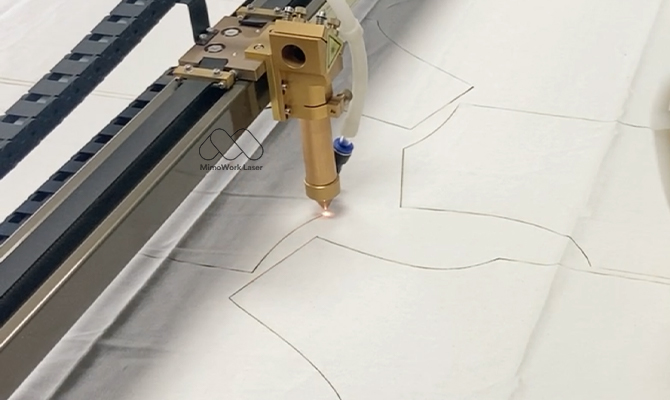

CO2 laser cutters with automatic conveyor tables are extremely suitable for cutting textiles continuously. In particular, Cordura, Kevlar, nylon, non-woven fabric, and other technical textiles are cut by lasers efficiently and precisely. Contactless laser cutting is an energy-concentrated heat treatment, many fabricators worry about laser cutting white fabrics may encounter brownish burning edges and have a significant effect on the subsequent processing. Today, we will teach you a few tricks on how to avoid over-burning on light color fabric.

Common Issues with Laser-Cutting Textiles

When it comes to laser-cutting textiles, there’s a whole world of fabric out there—natural, synthetic, woven, or knitted. Each type brings its own quirks that can impact your cutting experience. If you’re working with white cotton or light-colored fabrics, you might encounter some specific challenges. Here are a few common problems you might face:

>> Yellowing and Discoloration: Laser cutting can sometimes lead to unsightly yellow edges, which is particularly noticeable on white or light fabrics.

>> Uneven Cutting Lines: No one wants jagged edges! If your fabric isn’t cut evenly, it can throw off the whole look of your project.

>> Notched Cutting Patterns: Sometimes, the laser can create notches in your fabric, which can affect both aesthetics and functionality.

By being aware of these issues, you can better prepare and adjust your approach, ensuring a smoother laser-cutting process. Happy cutting!

How to Solve It?

If you’re facing challenges while laser-cutting textiles, don’t worry! Here are some straightforward solutions to help you achieve cleaner cuts and better results:

▶ Adjust Power and Speed: Over-burning and rough edges often stem from incorrect power settings. If your laser power is too high or your cutting speed is too slow, the heat can scorch the fabric. Finding the right balance between power and speed can significantly reduce those pesky brown edges.

▶ Improve Smoke Extraction: A strong exhaust system is crucial. Smoke contains tiny chemical particles that can stick to your fabric and cause yellowing when reheated. Make sure to remove smoke quickly to keep your fabric clean and bright.

▶ Optimize Air Pressure: Adjusting your air blower’s pressure can make a big difference. While it helps blow away smoke, too much pressure can tear delicate fabrics. Find that sweet spot for effective cutting without damaging your material.

▶ Check Your Working Table: If you notice uneven cutting lines, it could be due to an unlevel working table. Soft and light fabrics are particularly sensitive to this. Always inspect your table’s flatness to ensure consistent cuts.

▶ Keep the Workspace Clean: If you see gaps in your cuts, cleaning the working table is a must. Additionally, consider lowering the minimum power setting to reduce cutting power at the corners, helping to create cleaner edges.

With these tips in mind, you’ll tackle laser-cutting textiles like a pro! Happy crafting!

We sincerely recommend that you look for more professional advice about cutting and engraving of textiles from MimoWork Laser before investing a CO2 laser machine and our special options for textile processing directly from the roll.

What Added Value have MimoWork CO2 Laser Cutter in Textile Processing?

◾ Less waste due to Nesting Software

◾ Working tables of different sizes helps to process various formats of fabrics

◾ Camera recognition for the laser cutting of printed fabrics

◾ Different materials marking functions by mark pen and ink-jet module

◾ Conveyor System for the fully automated laser cutting directly from the roll

◾ Auto-feeder is easy to feed the roll materials to the working table, smoothing the production and saving labor cost

◾ Laser cutting, engraving (marking), and perforating are realizable in one single process without tool changing

FAQ

White fabrics get burnt edges due to a mix of heat sensitivity and technical factors. Here’s why:

Heat sensitivity: White/light fabrics lack dark pigments to disperse excess heat, making scorching more visible.

Wrong laser settings: High power or slow speed concentrates too much heat on edges, causing burning.

Poor smoke extraction: Trapped smoke carries residual heat, re-heating edges and leaving brown marks.

Uneven heat distribution: A warped table or inconsistent focus creates hot spots, worsening burns.

Yes, the laser type matters significantly for avoiding burnt edges on white fabrics. Here’s why:

CO₂ lasers (10.6μm wavelength): Ideal for white fabrics. Their adjustable power/speed settings let you control heat, reducing scorching. They’re designed for textiles, balancing cutting efficiency with minimal heat damage.

Fiber lasers: Less suitable. Their shorter wavelength (1064nm) generates intense, focused heat that’s harder to moderate, increasing the risk of burning light-colored fabrics.

Low-power vs. high-power lasers: Even within types, high-power lasers (without proper adjustment) concentrate excess heat—more problematic for heat-sensitive white fabrics than lower-power, finely tunable models.

Learn More About Fabric Laser Cutter and Operation Guide

Post time: Sep-07-2022