1. Isivinini Sokusika

Amakhasimende amaningi lapho ebonana nomshini wokusika nge-laser azobuza ukuthi umshini we-laser ungasika ngokushesha kangakanani. Ngempela, umshini wokusika nge-laser uyimishini esebenza kahle kakhulu, futhi isivinini sokusika ngokwemvelo siyinto ebaluleke kakhulu kumakhasimende. Kodwa isivinini sokusika esisheshayo asichazi ikhwalithi yokusika nge-laser.

Ngokushesha kakhuluukusika isivinini

a. Awukwazi ukusika izinto ezibonakalayo

b. Indawo yokusika iveza okusanhlamvu okugobile, kanti ingxenye engezansi yomsebenzi ikhiqiza amabala ancibilikayo

c. Unqenqema olunzima

Ijubane lokusika lihamba kancane kakhulu

a. Isimo sokuncibilika ngokweqile endaweni yokusika erhabaxa

b. Isikhala sokusika esibanzi kanye nekhona elibukhali kuyancibilikiswa kube amakhona ayindilinga

Ukuze imishini yokusika nge-laser idlale kangcono umsebenzi wayo wokusika, ungabuzi nje ukuthi umshini we-laser ungasika ngokushesha kangakanani, impendulo ivame ukungalungi. Ngokuphambene nalokho, nikeza i-MimoWork imininingwane yezinto zakho, futhi sizokunikeza impendulo enomthwalo wemfanelo.

2. Indawo Yokugxila

Ngenxa yokuthi ubuningi bamandla e-laser bunethonya elikhulu esivinini sokusika, ukukhetha ubude bokugxila kwelensi kuyiphuzu elibalulekile. Usayizi wendawo ye-laser ngemva kokugxila kwe-laser beam ulingana nobude bokugxila kwelensi. Ngemva kokuba ugongolo lwe-laser lugxilwe yilensi enobude obufushane bokugxila, usayizi wendawo ye-laser uncane kakhulu futhi ubuningi bamandla endaweni yokugxila buphakeme kakhulu, okuzuzisa ekusikeni kwezinto. Kodwa ububi bayo ukuthi ngokujula kokugxila okufushane, kuphela isibonelelo esincane sokulungisa ubukhulu bezinto. Ngokuvamile, ilensi yokugxila enobude obufushane bokugxila ifaneleka kakhulu ezintweni ezincane zokusika ngesivinini esikhulu. Futhi ilensi yokugxila enobude obude bokugxila inobubanzi bokugxila, inqobo nje uma inobukhulu bamandla obanele, ifaneleka kakhulu ekusikeni izinto zokusebenza ezijiyile njenge-foam, i-acrylic, kanye nokhuni.

Ngemva kokunquma ukuthi iyiphi ilensi yobude obuqondile okufanele isetshenziswe, indawo ehlobene nendawo yokugxila ebusweni bento yokusebenza ibaluleke kakhulu ukuqinisekisa ikhwalithi yokusika. Ngenxa yobuningi bamandla aphezulu endaweni yokugxila, ezimweni eziningi, indawo yokugxila iseduze noma ingaphansi kancane kobuso bento yokusebenza lapho inqunywa. Kuyo yonke inqubo yokusika, kuyisimo esibalulekile ukuqinisekisa ukuthi indawo ehlobene nendawo yokugxila kanye nendawo yokusebenza iyafana ukuze kutholakale ikhwalithi yokusika eqinile.

3. Uhlelo Lokuvuthela Umoya kanye negesi Esizayo

Ngokuvamile, ukusika nge-laser yezinto ezibonakalayo kudinga ukusetshenziswa kwegesi eyisizayo, okuhlobene kakhulu nohlobo kanye nokucindezela kwegesi eyisizayo. Ngokuvamile, igesi eyisizayo ikhishwa ngomsebe we-laser ukuze ivikele ilensi ekungcoleni futhi isuse i-slag phansi kwendawo yokusika. Ezintweni ezingezona ezensimbi kanye nezinye izinto zensimbi, umoya ocindezelwe noma igesi engasebenzi kahle isetshenziswa ukususa izinto ezincibilikisiwe nezihwamukile, kuyilapho kuvimbela ukusha ngokweqile endaweni yokusika.

Ngaphansi kwesisekelo sokuqinisekisa igesi elisizayo, umfutho wegesi uyisici esibaluleke kakhulu. Uma usika izinto ezincane ngesivinini esikhulu, umfutho wegesi ophezulu uyadingeka ukuvimbela i-slag ukuthi inamathele ngemuva kwesinqunyiwe (i-slag eshisayo izolimaza unqenqema olusikiwe lapho lushaya umsebenzi). Uma ukujiya kwezinto kukhuphuka noma isivinini sokusika sihamba kancane, umfutho wegesi kufanele wehliswe ngokufanele.

4. Izinga Lokuzindla

Ubude be-laser ye-CO2 buyi-10.6 μm okuyinto enhle kakhulu ukuthi izinto ezingezona ezensimbi zimunce. Kodwa i-laser ye-CO2 ayifanele ukusika insimbi, ikakhulukazi izinto zensimbi ezine-reflectivity ephezulu njengegolide, isiliva, ithusi kanye nensimbi ye-aluminium, njll.

Izinga lokumuncwa kwezinto eziya emshayweni lidlala indima ebalulekile esigabeni sokuqala sokushisa, kodwa uma umgodi wokusika usuvele ukhona ngaphakathi kwento yokusebenza, umphumela womzimba omnyama womgodi wenza izinga lokumuncwa kwezinto eziya emshayweni lisondele ku-100%.

Isimo sobuso bezinto ezibonakalayo sithinta ngqo ukumuncwa kogongolo, ikakhulukazi ubulukhuni bobuso, futhi ungqimba lwe-oxide yobuso luzobangela izinguquko ezisobala esilinganisweni sokumuncwa kobuso. Ekwenzeni ukusika nge-laser, ngezinye izikhathi ukusebenza kokusika kwezinto ezibonakalayo kungathuthukiswa yithonya lesimo sobuso bezinto ezibonakalayo esilinganisweni sokumuncwa kogongolo.

5. I-Nozzle Yekhanda Le-Laser

Uma umlomo ungakhethwanga kahle noma ungagcinwanga kahle, kulula ukubangela ukungcola noma umonakalo, noma ngenxa yokuzungeza okubi komlomo womlomo noma ukuvaleka kwendawo okubangelwa ukuchaphaza kwensimbi eshisayo, kuzokwakheka imisinga ye-eddy embotsheni, okuholela ekusebenzeni okubi kakhulu kokusika. Ngezinye izikhathi, umlomo womlomo awuhambisani nomqadi ogxilile, okwenza umqadi wokugunda umqadi womlomo, okuzothinta nekhwalithi yokusika umqadi, kwandise ububanzi bomqadi futhi kwenze usayizi wokusika uhlukane.

Kuma-nozzles, izinto ezimbili okufanele ziqashelwe ngokukhethekile

a. Ithonya lobubanzi be-nozzle.

b. Ithonya lebanga eliphakathi kwe-nozzle kanye nobuso be-workpiece.

6. Indlela Ebonakalayo

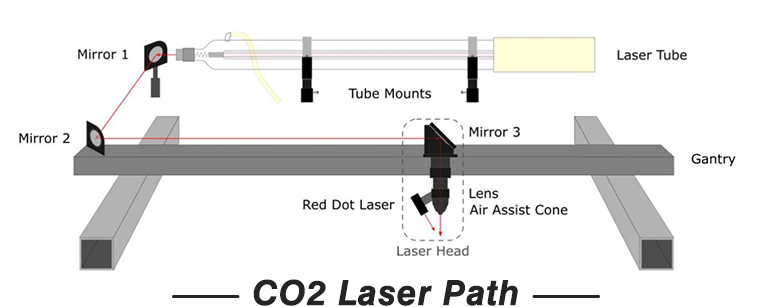

Ugongolo lokuqala olukhishwa yi-laser ludluliselwa (kufaka phakathi ukubonakaliswa kanye nokudluliselwa) ngohlelo lwendlela yangaphandle yokukhanya, futhi lukhanyisa ngokunembile ubuso bento yokusebenza ngamandla amakhulu kakhulu.

Izinto ezibonakalayo zesistimu yendlela yangaphandle yokukhanya kufanele zihlolwe njalo futhi zilungiswe ngesikhathi ukuqinisekisa ukuthi lapho ithoshi lokusika ligijima ngaphezu kwento yokusebenza, ukukhanya kudluliselwa kahle enkabeni yelensi futhi kugxilwe endaweni encane ukuze kusikwe into yokusebenza ngekhwalithi ephezulu. Uma indawo yanoma iyiphi into yokukhanya ishintsha noma ingcolisiwe, ikhwalithi yokusika izothinteka, futhi ngisho nokusika ngeke kwenziwe.

Ilensi yendlela yangaphandle yokukhanya ingcoliswa ukungcola okusemgwaqweni womoya futhi iboshwe yizinhlayiya ezisakazeka endaweni yokusika, noma ilensi ayipholi ngokwanele, okuzokwenza ilensi ishise kakhulu futhi kuthinte ukudluliswa kwamandla okukhanya. Kubangela ukuthi i-collimation yendlela yokukhanya ikhukhuleke futhi kuholele emiphumeleni emibi kakhulu. Ukushisa kakhulu kwelensi kuzophinde kubangele ukuphambuka okugxile futhi kufake ngisho nelensi uqobo engozini.

Funda kabanzi mayelana nezinhlobo zokusika nge-laser ye-co2 kanye namanani

Isikhathi sokuthunyelwe: Septhemba-20-2022