• Kula da Inganci a Walda ta Laser?

Tare da ingantaccen aiki, babban daidaito, babban tasirin walda, sauƙin haɗa kai ta atomatik, da sauran fa'idodi, walda ta laser ana amfani da ita sosai a masana'antu daban-daban kuma tana taka muhimmiyar rawa a cikin samar da walda ta ƙarfe da masana'antu, gami da a cikin sojoji, likitanci, sararin samaniya, sassan motoci na 3C, ƙarfe na ƙarfe na injiniya, sabon makamashi, kayan aikin tsafta, da sauran masana'antu.

Duk da haka, kowace hanyar walda idan ba ta ƙware a ƙa'idarta da fasaharta ba, za ta samar da wasu lahani ko samfura masu lahani, walda ta laser ba banda ba ce.

• Me ya kamata in yi don magance waɗannan lahani?

Kawai fahimtar waɗannan lahani ne, da kuma koyon yadda za a guji waɗannan lahani, don inganta darajar walda ta laser, sarrafa kyakkyawan kamanni, da kuma samfuran inganci.

Injiniyoyi ta hanyar tarin gogewa na dogon lokaci, sun taƙaita wasu lahani na walda na mafita, don ambaton abokan aikin masana'antu!

Mene ne Lalacewar Walda Biyar da Aka Fi Amfani da Su?

>> Fashewa

>> Raƙuman Weld

>> Fashewar

>> Ƙarƙashin Yanka

>> Rushewar Tafkin da aka Narkar

Idan kuna son ƙarin bayani game da HandHeld Laser Welders, zaku iya duba shafinmu don ƙarin bayanita hanyar link ɗin da ke ƙasa!

◼ Fashewa yayin walda ta Laser

Fashewar da ake samu a cikin walda mai ci gaba da laser galibi fasa ne masu zafi, kamar fasawar crystallization, fasawar ruwa, da sauransu.

Babban dalili shi ne cewa walda tana samar da babban ƙarfin raguwa kafin cikakken ƙarfi.

Yin amfani da na'urar ciyar da waya don cike wayoyi ko dumama ƙarfe kafin lokaci zai iya rage ko kawar da tsagewar da aka nuna yayin walda ta laser.

Fashewa a cikin Walda ta Laser

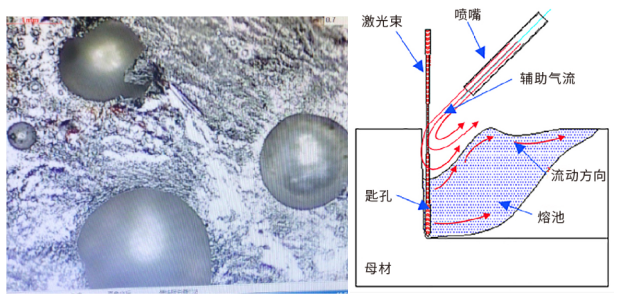

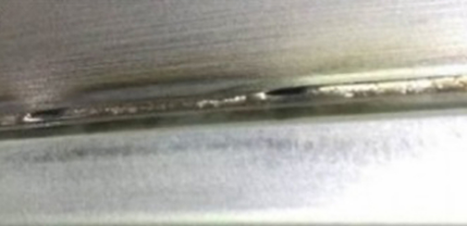

◼ Raƙuman da ke cikin Walda

Ramuka a cikin Weld

Yawanci, wurin walda na laser yana da zurfi da kunkuntar, kuma ƙarfe yawanci yana gudanar da zafi sosai kuma yana da sauri sosai. Iskar da ake samarwa a cikin wurin walda mai narkewa ba ta da isasshen lokacin da za ta iya fita kafin ƙarfen walda ya huce. Irin wannan yanayin yana da sauƙin haifar da samuwar ramuka.

Amma kuma saboda yankin zafi na walda na laser ƙarami ne, ƙarfen zai iya yin sanyi da sauri, kuma sakamakon porosity da aka nuna a walda na laser gabaɗaya ya fi ƙanƙanta fiye da walda ta gargajiya.

Tsaftace saman kayan aikin kafin walda na iya rage yawan ramuka, kuma alkiblar busawa zai kuma shafi samuwar ramuka.

◼ Fashewar

◼ Rushewar Tafkin da aka Narka

Ruwan da aka yi amfani da shi wajen walda ta laser yana shafar ingancin saman walda sosai kuma yana iya gurɓata da lalata ruwan tabarau.

Fashewar tana da alaƙa kai tsaye da yawan wutar lantarki kuma ana iya rage ta ta hanyar rage ƙarfin walda yadda ya kamata.

Idan shigar ciki bai isa ba, za a iya rage saurin walda.

Fashewar Laser Welding

Idan saurin walda yana da jinkiri, wurin narkakken wurin yana da girma da faɗi, yawan ƙarfen da ke narkewa yana ƙaruwa, kuma ƙarfin saman yana da wahalar kiyaye ƙarfe mai nauyi, tsakiyar walda zai nutse, ya ruguje ya kuma yi ramuka.

A wannan lokacin, ya zama dole a rage yawan kuzarin da ya dace domin guje wa rugujewar wurin narkakken ruwa.

Rushewar Tafkin da aka Narkar

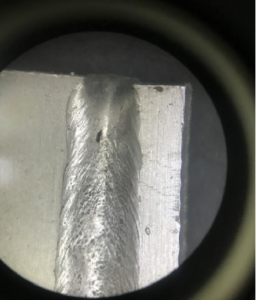

◼ Ƙarƙashin yankewa a cikin walda ta Laser

Idan ka yi walda da sauri sosai, ƙarfen ruwa da ke bayan ramin da ke nuni zuwa tsakiyar walda ba shi da lokacin sake rarrabawa.

Ƙarfafawa a ɓangarorin biyu na walda zai haifar da cizo. Idan tazara tsakanin sassa biyu ta yi yawa, ba za a sami isasshen ƙarfe mai narkewa da za a iya haɗa shi ba, wanda hakan zai sa cizon gefen walda ma ya faru.

A matakin ƙarshe na walda ta laser, idan kuzarin ya faɗi da sauri, ramin yana da sauƙin rugujewa kuma yana haifar da lahani iri ɗaya na walda. Ingantaccen ƙarfin daidaitawa da saurin motsi don saitunan walda ta laser na iya magance samar da cizon gefuna.

Ƙarƙashin yankewa a cikin walda ta Laser

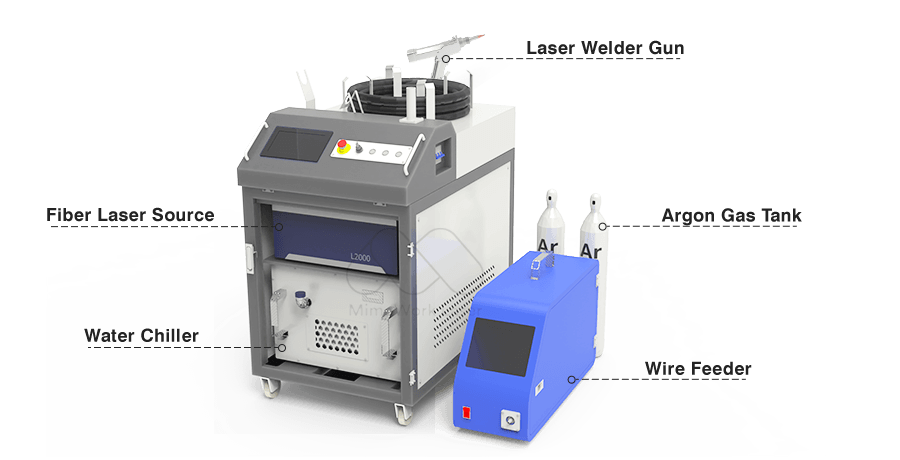

Masu walda na Laser na hannu don ku zaɓa

Kana son ƙarin bayani game da walda ta Laser?

Akwai wani rudani da tambayoyi game da injin walda na laser na hannu?

Lokacin Saƙo: Janairu-30-2023