• Ulawulo loMgangatho kwi-Laser Welding?

Ngobuchule obuphezulu, ukuchaneka okuphezulu, isiphumo esihle sokuwelda, ukuhlanganiswa okulula okuzenzekelayo, kunye nezinye izibonelelo, ukuwelda nge-laser kusetyenziswa kakhulu kumashishini ahlukeneyo kwaye kudlala indima ebalulekileyo ekuwelding ngesinyithi kwimveliso yemizi-mveliso nakwimveliso, kuquka emkhosini, kwezonyango, kwi-aerospace, kwiindawo zeemoto ze-3C, kwi-mechanical sheet metal, kumandla amatsha, kwi-sanitary hardware, nakwamanye amashishini.

Nangona kunjalo, nayiphi na indlela yokuwelda ukuba ayifundiswanga kakuhle umgaqo wayo kunye netekhnoloji, iya kuvelisa iziphene ezithile okanye iimveliso ezineziphene, ukuwelda nge-laser akunamahluko.

• Ndingenza ntoni ukuze ndisombulule ezo ziphene?

Kuphela kukuqonda kakuhle ezi ziphene, nokufunda indlela yokuphepha ezi ziphene, ukuze kusetyenziswe ngcono ukuwelda nge-laser, ukucubungula inkangeleko entle, kunye neemveliso ezisemgangathweni.

Iinjineli, ngokusebenzisa amava aqokelelweyo ixesha elide, zishwankathele ezinye zeziphene eziqhelekileyo zokuwelda kwisisombululo, ukuze zisetyenziswe ngoogxa babo kushishino!

Zithini Iziphene Ezintlanu Eziqhelekileyo Zokuwelda?

>> Iintanda

>> Iimbobo kwiWeld

>> I-Splash

>> UnderCut

>> Ukuwa kweChibi eliTyhidiweyo

Ukuba ungathanda ukwazi okungakumbi malunga nabaWelder beLaser ababanjwe ngesandla, ungajonga iphepha lethu ukuze ufumane ulwazi oluthe kratya.ngokusebenzisa ikhonkco elingezantsi!

◼ Iintanda xa kusenziwa i-laser Welding

Iimfantu eziveliswa kwi-laser continuous welding ikakhulu ziimfantu ezishushu, ezifana neemfantu ze-crystallization, iimfantu ezimanzi, njl.njl.

Isizathu esiphambili kukuba i-weld ivelisa amandla amakhulu okuncipha ngaphambi kokuba iqine ngokupheleleyo.

Ukusebenzisa i-wire feeder ukuzalisa iingcingo okanye ukufudumeza intsimbi kunganciphisa okanye kususe imingxunya ebonakala ngexesha lokuwelda nge-laser.

Iintanda kwiLaser Welding

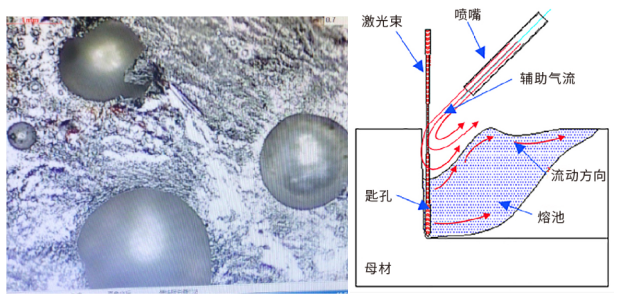

◼ Iimbobo kwiWeld

Iimbobo kwiWeld

Ngokwesiqhelo, ichibi lokuwelda nge-laser linzulu kwaye limxinwa, kwaye iintsimbi zihlala ziqhuba ubushushu kakuhle kwaye zikhawuleza kakhulu. Igesi eveliswa kwichibi elinyibilikisiweyo elimanzi ayinalo ixesha elaneleyo lokuphuma ngaphambi kokuba intsimbi yokuwelda iphole. Imeko enjalo kulula ukukhokelela ekwakhekeni kwee-pores.

Kodwa kwakhona ngenxa yokuba indawo yobushushu yokuwelda nge-laser incinci, isinyithi sinokuphola ngokukhawuleza, kwaye i-porosity ephumayo eboniswa kwi-laser welding ngokubanzi incinci kune-fusion welding yendabuko.

Ukucoca umphezulu wezinto zokusebenza ngaphambi kokuwelda kunokunciphisa ukuthambekela kweembobo, kwaye indlela yokuvuthela iya kuchaphazela ukwakheka kweembobo.

◼ I-Splash

◼ Ukudilika kweChibi eliTyhidiweyo

I-splash eveliswa yi-laser welding ichaphazela kakhulu umgangatho womphezulu we-weld kwaye inokungcolisa kwaye yonakalise ilensi.

Ukuchitheka kunxulumene ngokuthe ngqo noxinano lwamandla kwaye kunokunciphisa ngokunciphisa ngokufanelekileyo amandla okuwelda.

Ukuba ukungena akwanelanga, isantya sokuwelda sinokuncitshiswa.

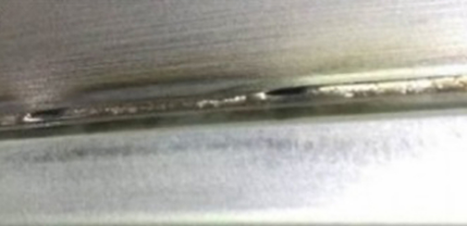

Ukuqhekeka kwi-Laser Welding

Ukuba isantya sokuwelda sicotha, ichibi elinyibilikisiweyo likhulu kwaye libanzi, ubungakanani besinyithi esinyibilikisiweyo buyanda, kwaye uxinzelelo lomphezulu lunzima ukugcina isinyithi esinzima solwelo, iziko lokuwelda liya kutshona, lenze ukudilika kunye nemingxuma.

Ngeli xesha, kuyimfuneko ukunciphisa uxinano lwamandla ngokufanelekileyo ukuze kuthintelwe ukudilika kwechibi elinyibilikisiweyo.

Ukudilika kweChibi eliTyhidiweyo

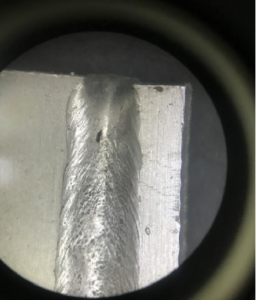

◼ Ukusikwa okungaphantsi kwe-laser Welding

Ukuba uyitshisile ngokukhawuleza kakhulu into yokusebenza yesinyithi, isinyithi esilulwelo esingasemva komngxuma esijonge embindini we-weld asinaxesha lokusasaza kwakhona.

Ukuqina kumacala omabini e-weld kuya kwenza ukuluma. Xa umsantsa phakathi kweziqwenga ezimbini zomsebenzi mkhulu kakhulu, akuyi kubakho sinyithi sinyibilikisiweyo esaneleyo sokufaka i-caulking, apho kuya kubakho nokuluma komphetho we-welding.

Kwinqanaba lokugqibela lokuwelda nge-laser, ukuba amandla ehla ngokukhawuleza kakhulu, umngxuma kulula ukuwudiliza kwaye oko kubangele iziphene ezifanayo zokuwelda. Amandla okulinganisela angcono kunye nesantya sokuhamba kwezicwangciso zokuwelda nge-laser kunokusombulula ukuveliswa kokuluma komphetho.

Ukusikwa okungaphantsi kwe-laser Welding

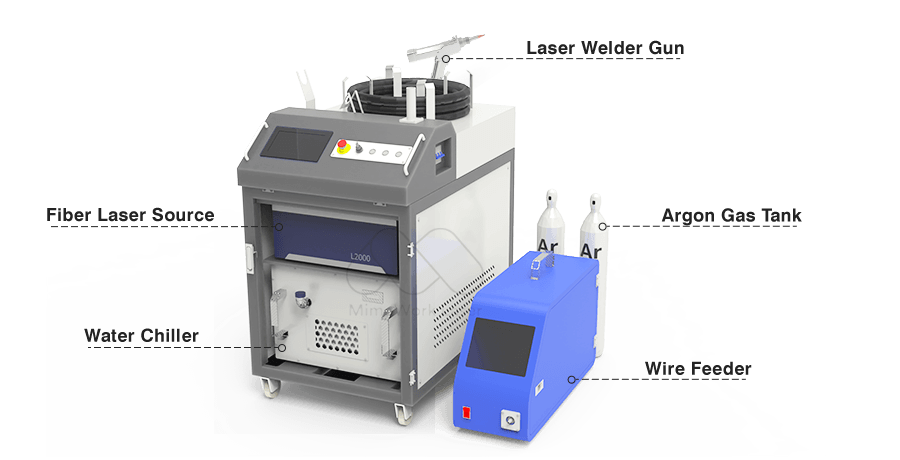

IiWelders zeLaser eziphathwayo onokukhetha kuzo

Ngaba ufuna ukwazi okungakumbi malunga nokuWelda ngeLaser?

Ngaba kukho ukudideka nemibuzo malunga nomatshini wokuwelda we-laser ophathwa ngesandla?

Ixesha lokuposa: Jan-30-2023